Please click one of the links below to jump to the desired section.

Baja Racing

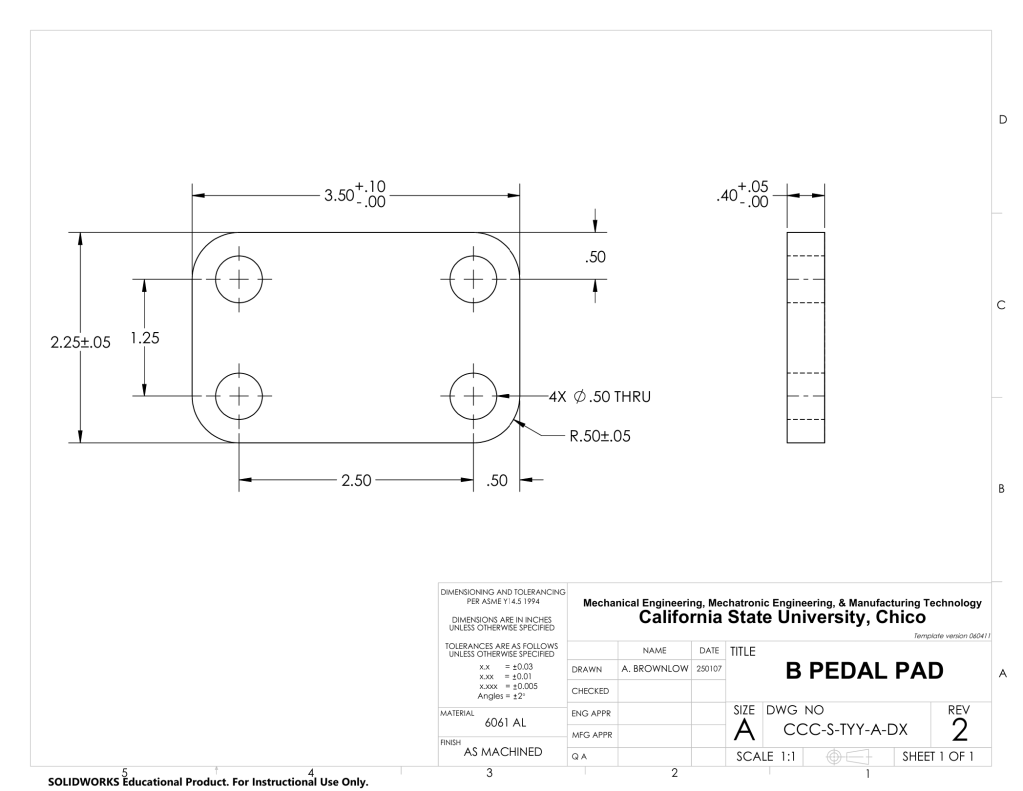

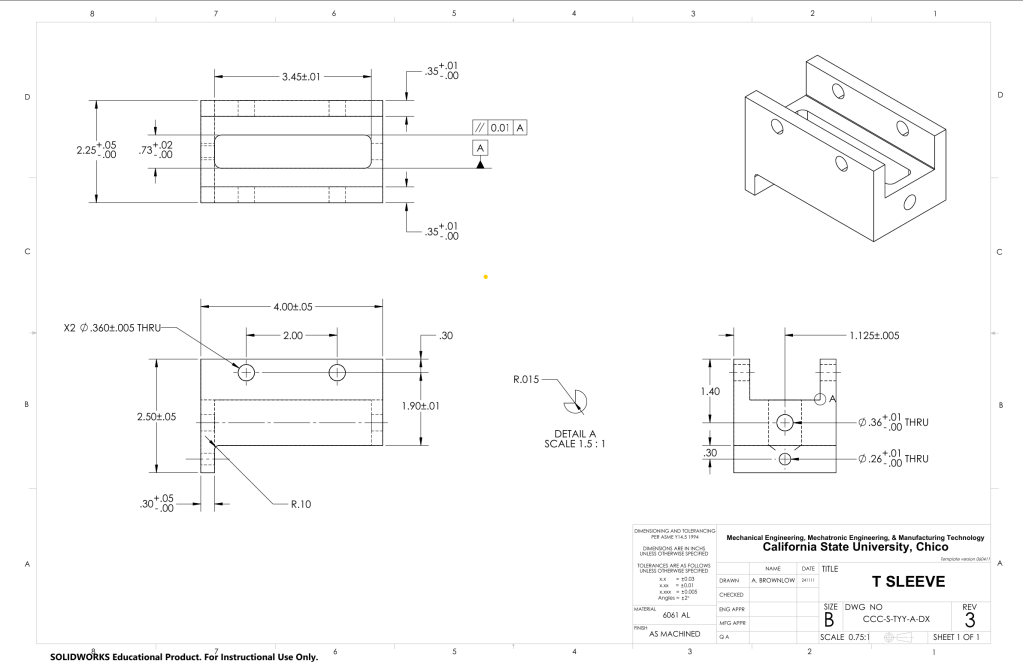

I joined Chico State’s Baja Racing team in fall of 2023. This was my freshman year and my very first semester in college. I spent my first year as a general member. There, I operated manual lathes and manual mills to produce parts, which would later contribute to the construction of our car. I interpreted ASME standardized engineering drawings, using skills like geometric dimensioning and tolerancing to manufacture a component within the tolerances required.

I was elected the Brakes and Throttle Officer in late spring of 2024. In this role, I researched and designed a braking system. I drafted over five assembly models with components that would be manufactured in-house, conducting finite element analysis on each before proceeding with my design. I then checked this design with manual and automated calculations, including a brake system calculator designed by previous leads and myself.

The image to the left in the first completed part that was manufactured for this project. The pedal pictured here was not used in the final system. It is comprised of two aluminum parts, manufactured using a manual mill, and two brass sleeves that were turned down on a manual lathe.

During production, I manufactured the majority of my system’s components on manual mills and lathes. I ensured that all components were within their required tolerances and would operate as expected. With the help of my team, the brakes and throttle system was successfully assembled. When we took our car to competition, the brakes performed perfectly.

As an officer, I learned how to design for manufacturing as efficiently as possible. I refined skills such as geometric dimensioning and tolerancing, conducting finite element analysis, and manual manufacturing. I applied my previous experiences working in a team to Baja, and our car successfully completed competition.

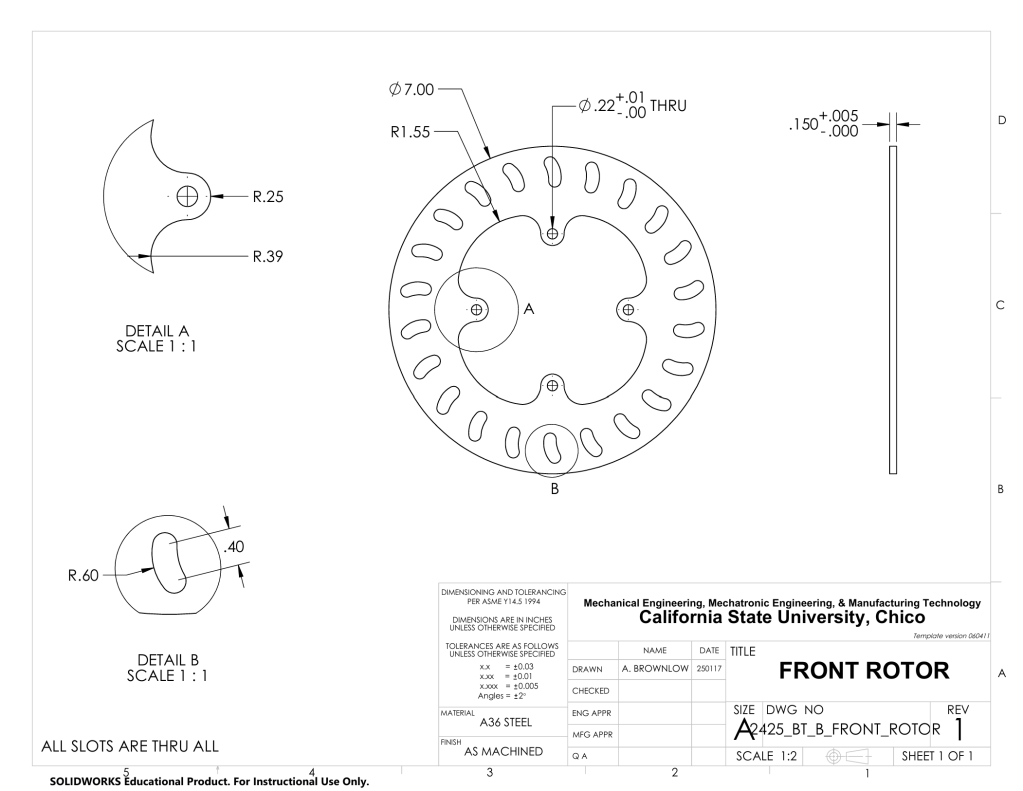

Engineering Drawing Details (click to expand)

All engineering drawings produced during CSU Chico Baja’s season underwent a comprehensive quality control system before being approved. First, drawings were reviewed for correct dimensioning, to ensure clear readability. Then the drawings were given a secondary review for manufacturability. If the drawings were found to be insufficient, the engineer revised their drawing until it was satisfactory. It was only after a part’s drawing passed quality control that it could be manufactured.

SolidWorks Assemblies and FEA

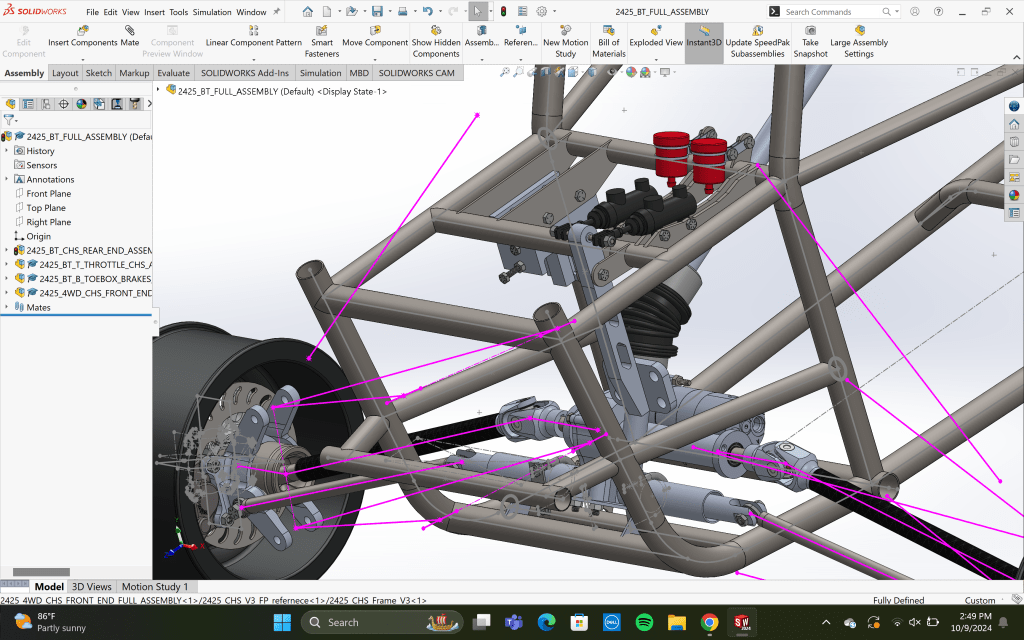

Prior to my stint as the brakes and throttle officer of CSU Chico’s Baja Racing, I had some experience with three dimensional modeling software in the form of Fusion360. This was rudimentary experience, which was expanded by engineering courses at CSU Chico and further refined while acting as an officer with Baja. As an officer, I modeled everything from simple spacers to system assemblies, and analyzed all components that would see loading with SolidWorks’ FEA simulations.

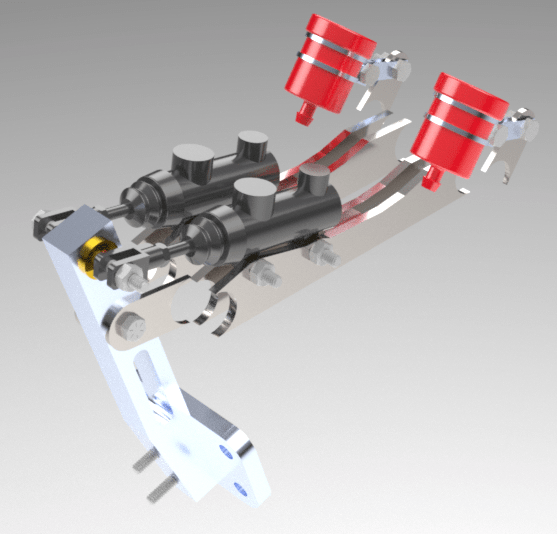

The image on the right is an assembly of the first draft of the system. This included off the shelf parts such as remote fluid reservoirs and master cylinders. All fasteners that would be seen on the physical vehicle are modeled here, courtesy of McMaster-Carr’s archives.

This assembly was constructed in reference to the chassis of the Baja vehicle, which was made up of steel tubing. It was used to place the steel tabs in the correct places and check clearances with other systems.

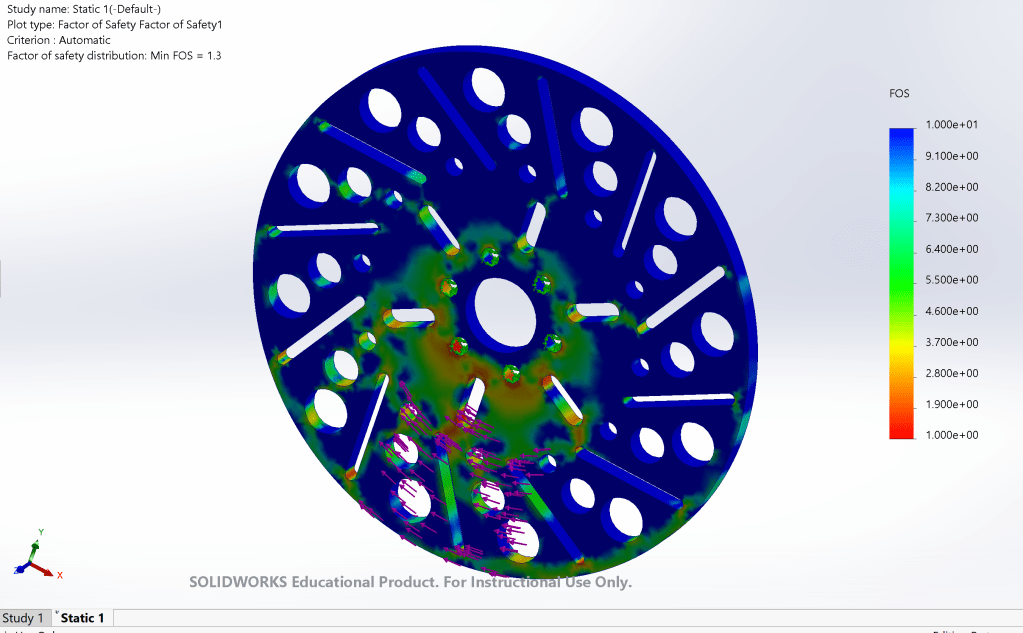

The image on the left is an FEA simulation of the single rear rotor that the 2025 Baja vehicle ran with. It was CNC milled, using 4045 steel for greater strength and heat resistance compared to milder steel alloys.

In the simulation, the rotor was fixed at the six mounting holes and saw a rotational force going clockwise. This modeled the act of braking at top speed with maximum braking torque, to analyze if the design was within expected tolerances.

Hoist Winch Manufacturing

My very first manufacturing project was the production of a hoist winch. The end product is a tool that can handle up two hundred and fifty pounds of loaded, with a ratchet function to extend and coil its steel cord. It is fully operational and is expected to last a significant amount of time.

This project served as an introduction to basic manual machines. This included manual lathes, manual mills, drill presses and jigs, hack saws and vices, and reamers.

Throughout production, I practiced interpreting standardized engineering drawings, with geometric dimensioning and tolerances. Each part was required to meet the given standards before the next could be manufactured. The hoist winch prepared me for more complex manufacturing, such as what was seen with the Baja brakes system.

The hoist winch is pictured to the left, lifting a two hundred and fifty pound “barrel” of concrete off of the ground.