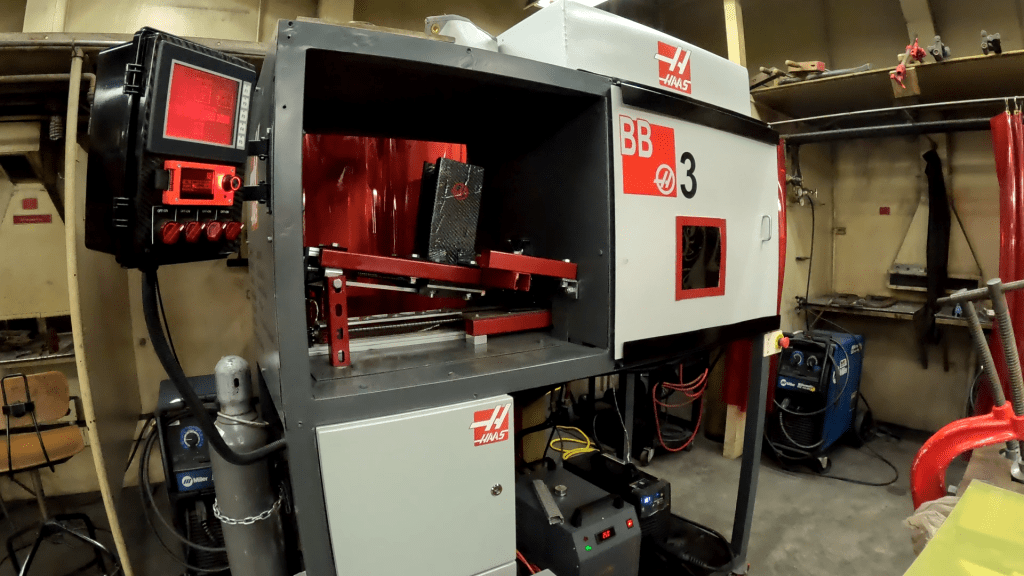

Build Bot 3.0

CSU Chico offers an incredible array of supportive programs for their students. Among them are research opportunities. This last summer, of 2025, I was able to dive into the world of research.

I worked closely with Dr. Stephanie Lawson to operate an in-house additive manufacturing machine, which has been dubbed Build Bot 3.0. During this self-led project, I explored how changes in parameters, such as current flow through the welder, effects the overall weld quality. By the end of the summer, I produced six usable samples, which were measured for data collection and graphed for comparisons.

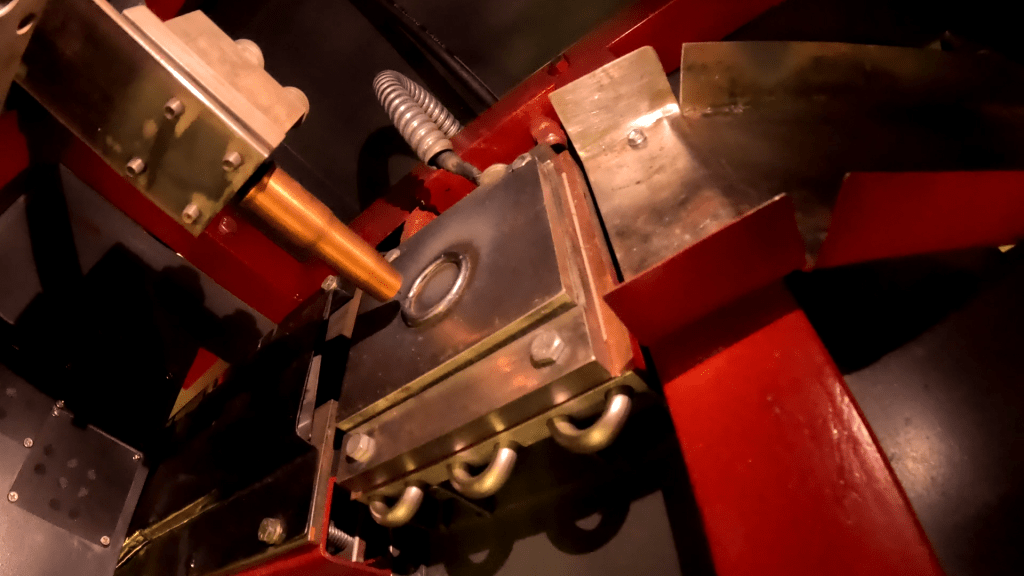

Weld Samples At Varying Currents (click to expand)

These three samples are two layers of steel wire, with a weld current of 83, 108, and 118 amps respectively. When the current is too low for the required power, the weld bead decreases in size and produces a sample that is below tolerance. When the current is too high, the weld bead increases in size and produces a sample above the given tolerance, requiring more secondary machining processes to par it down to size. 108 amps was determined by the previous student researchers as the ideal current, as it produced the most consistent weld.

At the conclusion of the research session, I presented my findings to eighty other student researchers at a mock research conference. I produced a poster and a PowerPoint. Currently, I am in the process of conducting a cost analysis of the production. This cost analysis, as well as my research itself, will be published in a scientific journal and enable me to share my research at national conferences.